How CNC machining is enhancing manufacturing

Whether your manufacturing business has been on the market for a while or you are new to the game, learning about technologies to improve your business and production operations will ensure a successful business future. So, there’s a good chance you’ve already heard about CNC machining.

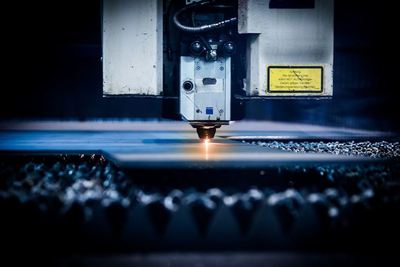

Computer Numerical Control (CNC) machines have enabled small and mid-sized manufacturers to stay competitive against the big-name companies by providing the means to rapidly increase productivity via computerization and automation.

Today, CNC machines are widespread. These machines are dominating the manufacturing world, allowing for a significant jump in productivity across the globe.

Here’s how CNC is improving manufacturing by the day.

The Role of CNC Machines in Manufacturing

CNC machining utilizes computers to regulate the entire manufacturing process. Essentially, it takes computer automation to an entirely new degree. Manufacturers are able to input the specific details of what should be done and leave the CNC machines to carry out the rest of the work with little to no supervision.

Mills, lathes, drills, and many other devices will all remain working as long as required, doing whatever is needed with little human input.

Because CNC parts have exceptional accuracy and material properties, CNC machining is currently one of the few manufacturing processes suitable for creating parts for critical space applications. Not to mention the variety of surface treatments you can apply to the parts after machining.

With the development of CNC technology, we have seen a plethora of advancements applied far beyond the CNC industry, e.g., improved engine communications and simplified programming language. As it continues to advance, we can rest assured that plenty of more exciting improvements in CNC are yet to come.

How Do These Machines Work?

CNC machines comprise of computers where the program is fed for cutting of the metal of the job as required. All the cutting processes and final dimensions are fed into the computer via the program. That’s how the computer knows what to be done, carrying out all the cutting processes. So, basically, a CNC machine works like a robot - it is fed via the program and follows your instructions.

Some common machine tools that run on the CNC include lathe, drilling machine, milling machines, etc. The key purpose of these CNC machines is to eliminate some of the metal to give it a proper shape like round, rectangular, and so on.

The role of an operator in CNC machines is greatly reduced. The operator only has to feed the program of instructions on the computer and then load the necessary tools into the machine. After that, the rest is performed automatically by the computer itself.

6 Ways CNC Machining is Improving Manufacturing

Ultra Convenience

With CNC machines, there’s a great reduction in manual work. This saves time and makes production operations more efficient and smooth. Automated operations are usually faster compared to manual human input. Digitized manufacturing further helps in reducing human errors and is able to operate whenever required.

For those wondering if CNC machining will completely replace human-led operations, as intimidating as it may sound, CNC machines are not here to replace humans, but to empower us to make our daily tasks more pleasant.

Fewer processes

When it comes to CNC machine monitoring, computers and software are the two main parts. CAD model preprograms the sought projects and uploads data to the device. Another great advantage of this technology is that it has the ability to perform almost every producing step by itself. This eliminates the call for additional machines and tools or even manual work.

Sustainability

CNC machining tends to drive sustainability in a number of ways. The technology does not demand any additional materials, meaning it doesn’t leave any waste. It also has little to no chances of making errors. This prevents tossing parts and materials away and wasting crucial production time.

Moreover, CNC machining does not require any additional parts, such as separate sanders or drills, as it has pretty much everything embedded in the body.

Prototype Machining

In the world of manufacturing, prototyping is extremely crucial as it helps in avoiding errors in the production process later on. It also helps to understand the product better. That said, many manufacturers skip the prototyping bit or do not invest sufficient time in it due to the fact that it is costly and time-consuming.

Thanks to CNC machining, prototyping is now more affordable than ever. It’s also easier to attain. Manufacturers are able to craft mock-ups and get a clear idea of what the next step will be in the process. The CNC machining technology navigates through a variety of manufacturing processes and enables developing more complex designs.

Affordable

Besides being compact in size, the price tag on CNC machines is also decreasing, meaning people can now invest in their own machinery and carry out critical production work on-site, instead of having to outsource costly work overseas.

More Employment Opportunities

It may seem like using a machine to perform the majority of operations would replace rather than create job opportunities, but it’s actually the opposite.

Although there’s no need to hire workers to carry out the job the machine is doing (e.g., drilling, cutting, boring), new job roles will emerge requiring more and more people to maintain the machines, supervise production, examine the output quality, sales, installation, troubleshooting, and so on.

Wrapping Up

Manufacturers need to start thinking of CNC machining and its future if they aren’t already. Rapid prototyping and other services in the CNC industry, are already being automated. Businesses that don’t opt for automation are basically being left behind.

There are a variety of reasons to automate, with some being to stay super competitive and cut a big chunk of manufacturing expenses.

Staying competitive indicates delivering higher-quality products at a larger scale to consumers faster than your competitors can. Luckily, CNC machining automation can help reduce waste, which, in turn, helps businesses cut expenses.

While the changes to an automated industry may cost a fortune, the pros are endless, so much so that businesses will soon be left behind if they don’t take this path.