Xtrac exceeds 2 million IndyCar miles as it prepares new gearbox

Xtrac, a global leader in motorsport transmissions, will this weekend mark its two millionth milestone in the North American IZOD IndyCar Series as it prepares its specification for a lightweight transmission for the new chassis being introduced in 2012. The UK and USA based gearbox manufacturer has been an exclusive supplier to the series over the past 10 years.

Xtrac’s unrivalled reputation for supplying premier league motorsport teams with reliable high-technology transmission systems, which help to optimise vehicle performance while reducing downtime and minimising running costs, should prove a significant factor in the development of an advanced lightweight gearbox to suit the new engine specification, following the recent decision by the ICONIC (Innovative, Open-Wheel, New, Industry-Relevant, Cost-Effective) advisory committee and the IZOD IndyCar Series to introduce a brand new chassis strategy for 2012.

“Passing this momentous milestone marks a highly successful decade and longstanding relationship with one of the greatest race series in the world,” says Peter Digby president and managing director at Xtrac. “We now look forward to submitting our proposals for a new lightweight transmission and would like to take this opportunity to congratulate Dallara for winning the contract to supply the new chassis. We have already indicated to the series promoters that we are willing to relocate to the new Speedway redevelopment area, which is very close to our existing facility in Indianapolis, where we’ve been based since 2003.”

The local relocation by Xtrac would put it even closer to Dallara’s new state-of-the-art technology centre to be located on Main Street, which was recently announced by the Speedway Redevelopment Commission (SRC). Dallara has stated that it will encourage its distributors and other businesses to also move into Speedway’s 700-acre redevelopment area, which broke ground with its first construction project in November 2009, ‘to continue to foster the growth of a vibrant, racing-centred community’.

“We would look like to thank Xtrac for its longstanding support as exclusive supplier of transmissions for the IZOD IndyCar Series since 2000 and for its commitment to have a base in Indiana since 2003,” says Brian Barnhart, president of competition and racing operations. “We are equally delighted that Xtrac has committed to relocate to our new redevelopment area and of course we wish them every success in their discussions with Dallara for a new lightweight gearbox suitable for the new chassis.”

As a major international customer, the IZOD IndyCar series typifies for Xtrac the global nature of its business and represents a significant contract that has been successfully renewed six times since 2000 and which currently extends to the end of 2011.

“It’s serious business, but it’s also tremendous fun and deeply satisfying designing a gearbox able to handle the prodigious power of a 650bhp race car capable of reaching speeds in excess of 230mph,” says Digby. “We also applaud the ICONIC’s mission to reach out and challenge the automotive and aerospace industries to join in and enhance the relevancy of the series with advanced and innovative technology. We are fully supportive of technology transfer between industry sectors as demonstrated by our recent success at transferring motorsport technology into the military sector.”

The targeted minimum weight for the new car is 1,380 pounds (625kg), nearly 200 pounds (90kg) lighter than the current car.

“This will require a significant weight saving for the transmission without compromising reliability and our well established low running costs,” says Digby. “This will be an interesting and exciting challenge for our technical capabilities, and we’ll draw heavily on our experience in other premier motorsport series including our major involvement in Formula 1 and in the Le Mans 24 hour race”.

Currently halfway through the IZOD IndyCar 2010 racing season the two millionth milestone for racing, practise and testing will be exceeded during the next race, which will be held this coming Sunday 25 July at the Edmonton city centre airport circuit in Alberta, Canada.

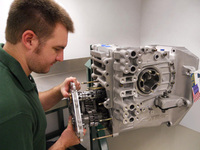

“Our first IndyCar transmission was introduced in 2000 to improve race car reliability, driver safety, and to provide the series with a more robust and more durable gearbox,” adds vice president Andrew Heard who heads up the Xtrac Inc. operation based in Indianapolis. “We have delivered an exemplary record of reliability and performance – with some teams still running some of the early casings. To handle the power of an IndyCar all of the steel used for the rotating parts is produced to our own metallurgical specification, with strict quality control procedures carried out at every manufacturing stage.”

The first generation transmission was designed specifically to fulfil the IndyCar technical and commercial regulations says Heard: “To meet the requirements we put a lot of effort into achieving the lowest possible running costs, whilst ensuring that technically we had designed a reliable transmission built to the highest motorsport industry standards . A high level of design engineering effort went into this project, and the same standards will be applied to the new transmission.”

The year 2000 was an important time for Xtrac. It not only secured its exclusive contract to supply the Indy Racing League (as it was then known), but also relocated to a brand-new factory constructed on a 13-acre site at Thatcham near Newbury in England. By 2003 the company had established Xtrac Inc based in Indianapolis primarily to support the IndyCar series.

The legendary Indianapolis 500 race is the highlight of this famous open wheel racing series and is generally considered as one of the three most prestigious motorsport races in the world alongside the Formula One Monaco Grand Prix and the 24 Hours of Le Mans – in both races many of the teams also compete with Xtrac transmissions.

The current IZOD IndyCar 6-speed transaxle applies more than 25 years of Xtrac experience supplying to the world’s top racing formulae and adopts the same design principles to minimise the mass, size and inertia. For the second generation transmission particular attention was paid to the gearshift and in 2008 Xtrac upgraded the transmission with a MegaLine Assisted Gearchange System supplied to every IndyCar chassis, which has been a great success further reducing running costs while enhancing driver safety.

Xtrac opened its new facility in Indianapolis for the start of the 2003 season, located just a few minutes’ drive from the famous Indianapolis Motor Speedway. The 6,900 square foot (640m2) building is equipped to offer engineering and spares support for the North and South American markets. This also includes gearbox servicing and track support for the GRAND-AM Sportscar Series, American Le Mans Series, and desert and closed-course off road racing. In 2008, Xtrac Inc. further expanded its Indianapolis operation and began locally assembling and sourcing components for IndyCar and this programme would be further expanded for the new transmission.