Promoting the re-use of plastic parts: Recycling guides at daf.com

In order to facilitate and encourage the recycling of plastic parts, DAF Trucks has created recycling guides for the new LF and CF series, as well as the XF105 series, which was voted 'International Truck of the Year 2007'. These recycling guides can be found at daf.com.

In order to facilitate and encourage the recycling of plastic parts, DAF Trucks has created recycling guides for the new LF and CF series, as well as the XF105 series, which was voted 'International Truck of the Year 2007'. These recycling guides can be found at daf.com.In terms of weight, over 80% of a modern DAF truck can be re-used; of the metals used that is over 90%. Of the plastic parts used, around 80% are suitable for recycling. In order to re-use all of these parts it is necessary to identify what type of material each one is made from, which is why DAF marks all plastic truck parts with a code. Dealers and vehicle breakers can use this code to sort plastic waste for re-use.

Recycling guides

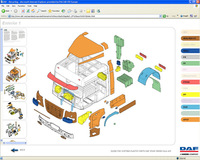

To make sorting plastic parts even easier, DAF has also created recycling guides for the new LF, CF and XF105 series in which all the plastic components used are colour coded by material type. Just like the existing recycling guides for models from 1997 onwards, the new guides are available to download at daf.com.

DAF Trucks N.V. has been active in the recycling and re-use of components since 1970. In DAF's Overhaul Workshop in Eindhoven, around 85,000 parts are overhauled and supplied for re-use every year. These include engines, gearboxes, differentials, alternators, starter motors, as well as fuel and air pressure components.

DAF's recycling policy is part of its environmental policy, under which the complete lifecycle of the truck is considered, from development to scrapping. In 1998, DAF was one of the first truck manufacturers with an ISO 14001 certified environmental protection system.