Allison T375 and T375R to satisfy higher power and torque engines

With bus engine power and torque outputs increasing, Allison Transmission has announced an addition to its trusted Torqmatic range. Debuting at Busworld 2009, the latest six speed automatic models are ideal for bus and coach applications up to 360bhp and 1450Nm torque. The new T375 and retarder derivative T375R will compliment the current offerings of Allison mid range fully automatic transmissions assuring coverage in this segment for new Euro 5 engines. In addition the transmission debuts key fuel saving technology features that are being rolled out across the Allison range.

With bus engine power and torque outputs increasing, Allison Transmission has announced an addition to its trusted Torqmatic range. Debuting at Busworld 2009, the latest six speed automatic models are ideal for bus and coach applications up to 360bhp and 1450Nm torque. The new T375 and retarder derivative T375R will compliment the current offerings of Allison mid range fully automatic transmissions assuring coverage in this segment for new Euro 5 engines. In addition the transmission debuts key fuel saving technology features that are being rolled out across the Allison range.“Tighter emissions control and the need to still deliver performance are pushing engine power outputs higher,” says Allison’s european marketing manager Manlio Alvaro. “The new T375 will ensure excellent reliability and with the very latest control technology and hardware upgrades also increases efficiency.”

The T375 and T375R also feature Allison 4th Generation Controls. These controls allow full integration with CAN-based vehicle architectures offering OEMs better powertrain control

strategies. Drivetrain performance is enhanced thanks to the latest versions of Closed-loop Adaptive Logic for outstanding shift quality; Auto Neutral, RELS, new Eco Calibration and Load Based Shifting Scheduling technology for superior fuel efficiency.

The Eco Calibration package ensures the engine operates within a narrow operating speed band whilst preventing shift cycling. Together with the latest Load Based Shift Scheduling (LBSS) technology, which automatically selects between pre-determined shift schedules factoring in topography and vehicle load, enable maximum fuel economy and maintain vehicle performance. For Shift Energy Management (SEM) capable engines, as of 2010, LBSS will be enhanced with Super Economy Shift Schedule (SESS) that upshifts the transmission to higher gear at cruise ensuring the minimum traction effort requirements. Opportunity to make an upshift in steady-state is greater with SESS, and average engine speed operation is reduced. Furthermore, Vehicle Acceleration Control system (VAC) will be available for customers who require bus acceleration limitation via torque management.

On-road test results demonstrate that the combination of Allison’s features can deliver up to 14 percent reduction in fuel consumption.

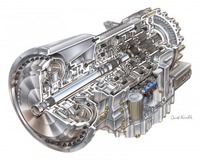

The T375 and T375R models incorporate all the key features from the trusted bus-specific Torqmatic® range. Allison patented Polak gear scheme provides six speeds with the same number of planetary gear sets as other four speed transmissions and assures superior durability and power transmission efficiency. The precision helical cut gears reduce noise inside and outside the bus.

In line with the trend for engines to deliver more power, the cooling system now includes an enhanced 17 plate Integral Cooler and optional Integral Sump Cooler. To assure optimum

cooling during retarder operation, the Integral Sump Cooler core has two compartments: one compartment for the retarder oil and one compartment for sump oil. This provides an additional circuit for oil flow during retarder operation, resulting in lower transmission sump temperatures therefore less oil degradation and improved product life.

As part of Allison Transmission’s continuous product improvement initiative, all Allison Torqmatic transmissions are now available with prognostics that determine health of the transmission, and when a specific maintenance function is required. “Allison Prognostics take the guesswork and hassle out of scheduling routine vehicle maintenance to save you time and money while providing maximum protection for the transmission,” adds Alvaro. “That means less downtime, lower life-cycle costs and, best of all, greater productivity for your fleet.” Allison Prognostics also eliminates unnecessary fluid and filters changes, significantly reducing oil usage and avoiding unnecessary changes.

Allison customers for the new T375 and T375R models will also have access to Allison’s optional Extended Transmission Coverage package, providing up to 5 years‘ of coverage. The T375 and T375R models are part of Allison’s extensive range of gearboxes offering solutions for buses and coaches from 200bhp to over 500bhp.Temsa Global has selected the Allison T375R as the standard transmission in the CNG fuelled version of their recently introduced Avenue city bus.“We expect these new models to be popular additions to the increasing number of transmissions we are building for global bus and coach applications,” claims Alvaro.